End2End Solutions

Machine Maintenance System

Bringing Traceability to Needle Issuance Level

Machine Maintenance System is an intelligent way to handle spare parts inventory and keeping track of parts issued to any specific machine type. Machine Transfer to any line is also accounted for by the system.

Challenges in Maintenance

Tracking Machines or Assets movement and Location

No Inventory Record

There are issues of maintaining proper inventory of spare parts after issuance during any maintenance activity. Theft cases are also encountered due to lack of such traceability.

Shortage of Spare Parts

Often the most used spare parts gets short in the inventory due to lack of alerts or planning. It halts the whole maintenance activity which causes wastage of valuable time and efforts.

Unauthorized Movement of Machines

Machines often get transferred to different lines without any prior permission and there in no record in the system about updated location of machine.

Machine Maintenance Feature Set

Pre-planned alerts can be generated from the system for planned maintenance or movement of machines and also for planned assignment of assets to specific recipient at specific time in future. Any unplanned or unauthorized movement of machines and assets can also be tracked and at once reported to the concerned department.

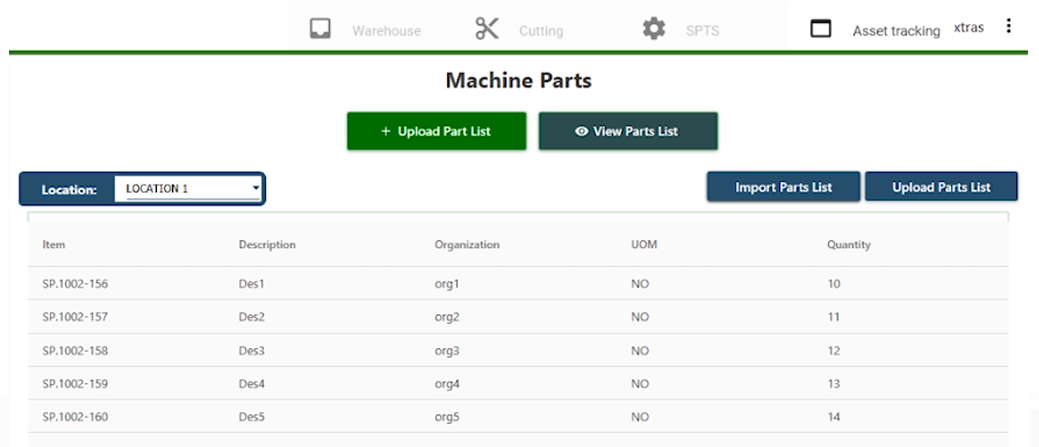

Inventory List Upload

1. Inventory list is uploaded into the system through an excel file or manual entry.

2. This inventory gets updated with issuance of any spare parts to a maintenance activity and record is maintained.

3. Parts with low quantity that can become bottle neck of maintenance activity are highlighted in real time.

Machine Maintenance Feature Set

Spare Parts Issuance

1. Spare Parts are issued to a specific machine type for maintenance activity.

2. Quantity of parts after issuance are updated in the inventory and reports generated from this information shows the breakdown of each part issued.

3. Parts that are often issued are highlighted for management to be able to plan their availability beforehand so that the maintenance activity doesn’t get affected.

Machine Maintenance Feature Set

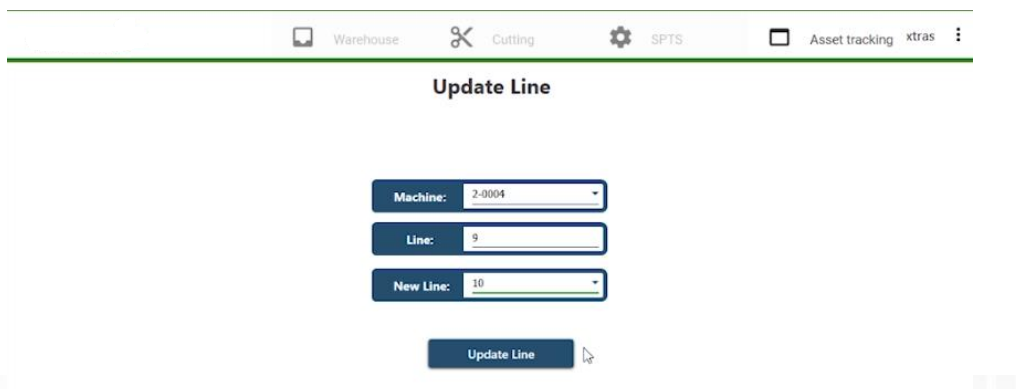

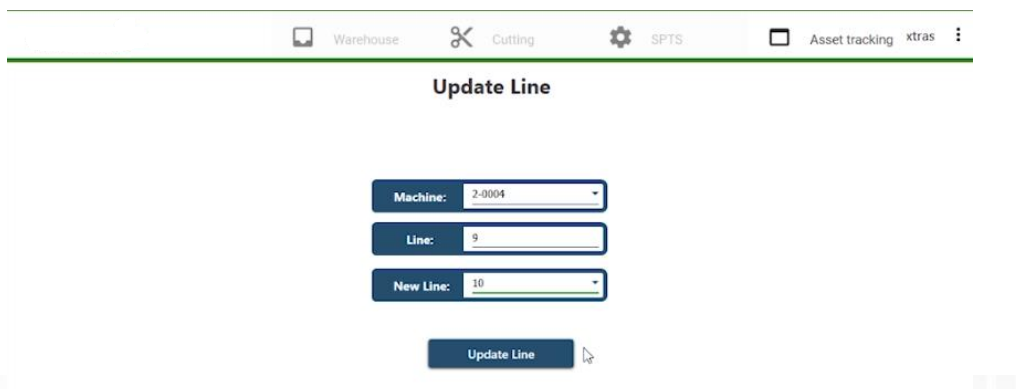

Machine Transfer

1. Current location of the machine is shown when a machine is selected from a drop down menu

2. New location is set by the operator and machine is transferred through a user friendly application.

3. System gets automatically updated with machine being placed in a specific line and helps in assigning any new operations in that line

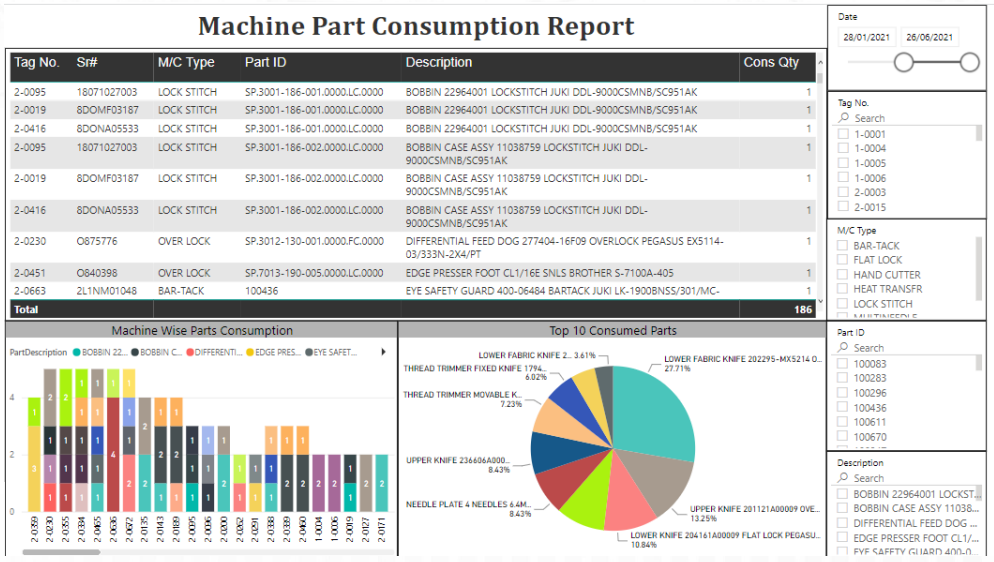

Machine Maintenance Reports

1. Spare Parts are issued to a specific machine type for maintenance activity.

2. Quantity of parts after issuance are updated in the inventory and reports generated from this information shows the breakdown of each part issued.

3. Parts that are often issued are highlighted for management to be able to plan their availability beforehand so that the maintenance activity doesn’t get affected.

Machine Maintenance Feature Set

Machine Transfer

1. Current location of the machine is shown when a machine is selected from a drop down menu

2. New location is set by the operator and machine is transferred through a user friendly application.

3. System gets automatically updated with machine being placed in a specific line and helps in assigning any new operations in that line

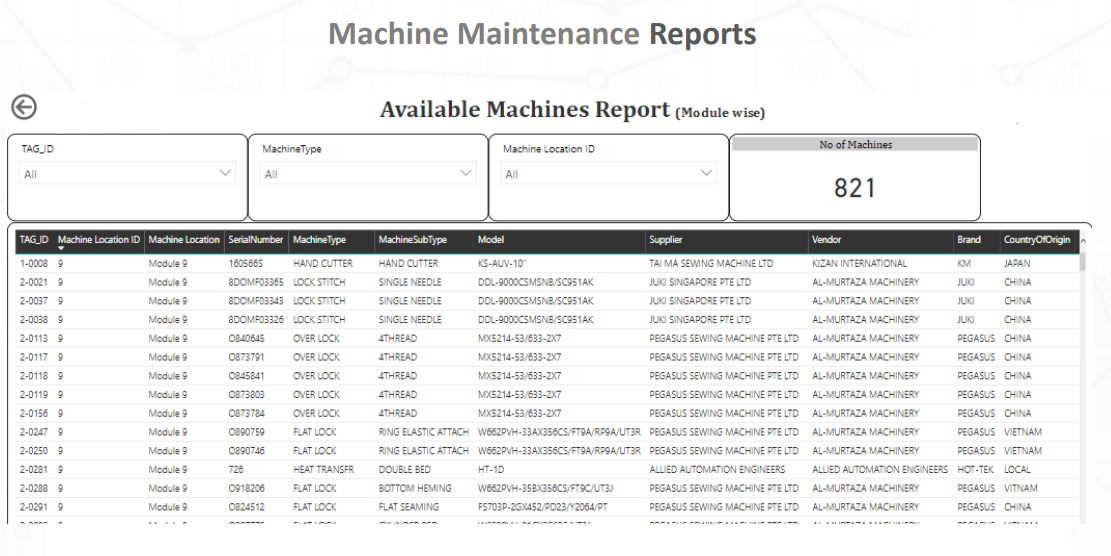

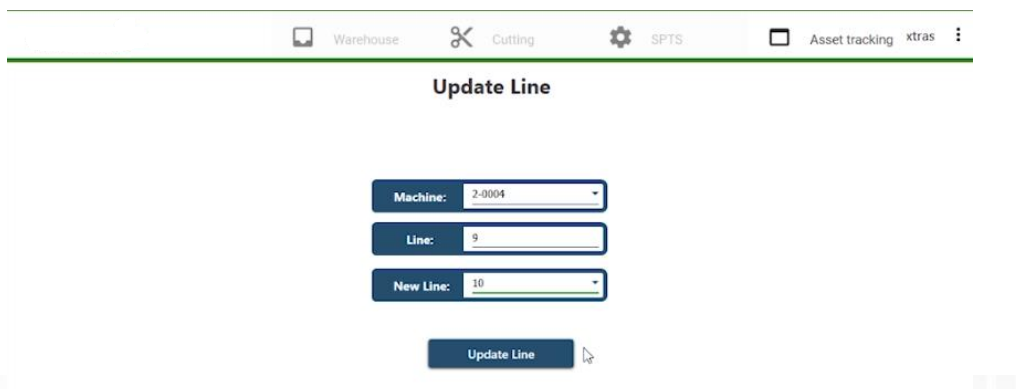

Machine Maintenance Reports

1. Current location of the machine is shown when a machine is selected from a drop down menu

2. New location is set by the operator and machine is transferred through a user friendly application.

3. System gets automatically updated with machine being placed in a specific line and helps in assigning any new operations in that line